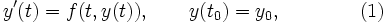

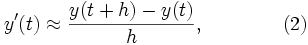

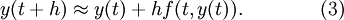

Modelling the cloth

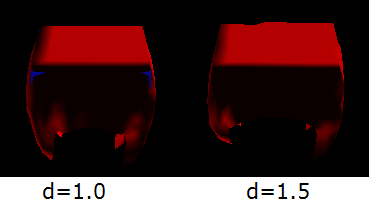

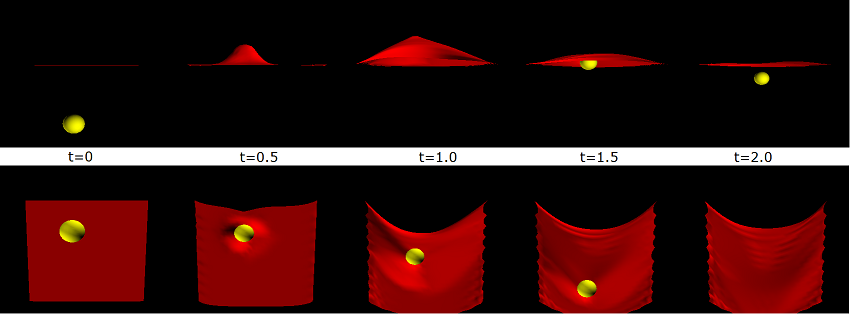

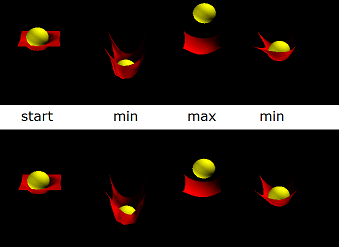

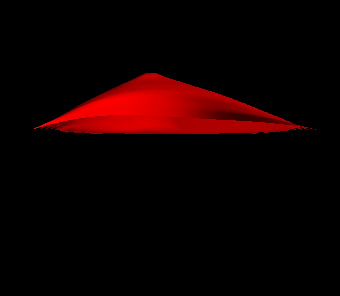

Building on the framework and GUI from the Animator project, we implemented a cloth simulation based on a particle system with springs. Each particle of the cloth is connected horizontally and vertically to each direct neighbors (springs controlling the stretch of the fabric), as well as diagonally (springs controlling the shear of the fabric). To control the bending of the fabric (creating ripples), there also need to be springs connecting the second neighbor horizontally and vertically. We found out that these connections are enough to create a quite stable and realistic looking cloth that can be simulated with an Euler ODE solver. The springs connecting particle i,j to its neighbors in the mesh is shown at the left. At the borders of the cloth, there are obviously less springs because of missing neighbors. Since we implemented the springs to work both in pushing as well as pulling direction, this is not a problem.

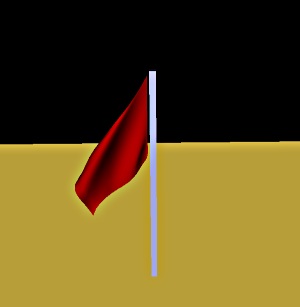

In the Animator, various properties of the cloth can be controlled directly by sliders, such as the dimensions, the density of particles, their masses, or the number of fixed (attached) points along each edge. To animate the cloth, the wind strength and direction can be set, as well as controlled with interpolating curves over the duration of the animation.

The cloth is rendered by storing the particles as coordinates in a OpenGL Quadmesh. For correct shading, we compute the surface normals with a cross-product.

Figure 1: Springs connecting one particle